When your project demands professional-grade mixing performance, choosing the wrong paddle can cost you time, materials, and money. Construction professionals know that lumpy adhesives and inconsistent mixes spell disaster for tile installations and flooring projects.

The Collomix KR120HF Mixing Paddle transforms this challenge into smooth, efficient mixing operations. This German-engineered tool delivers consistent results across various construction materials, making it a cornerstone for contractors seeking reliability in their toolkit.

Engineering Excellence Behind the Design

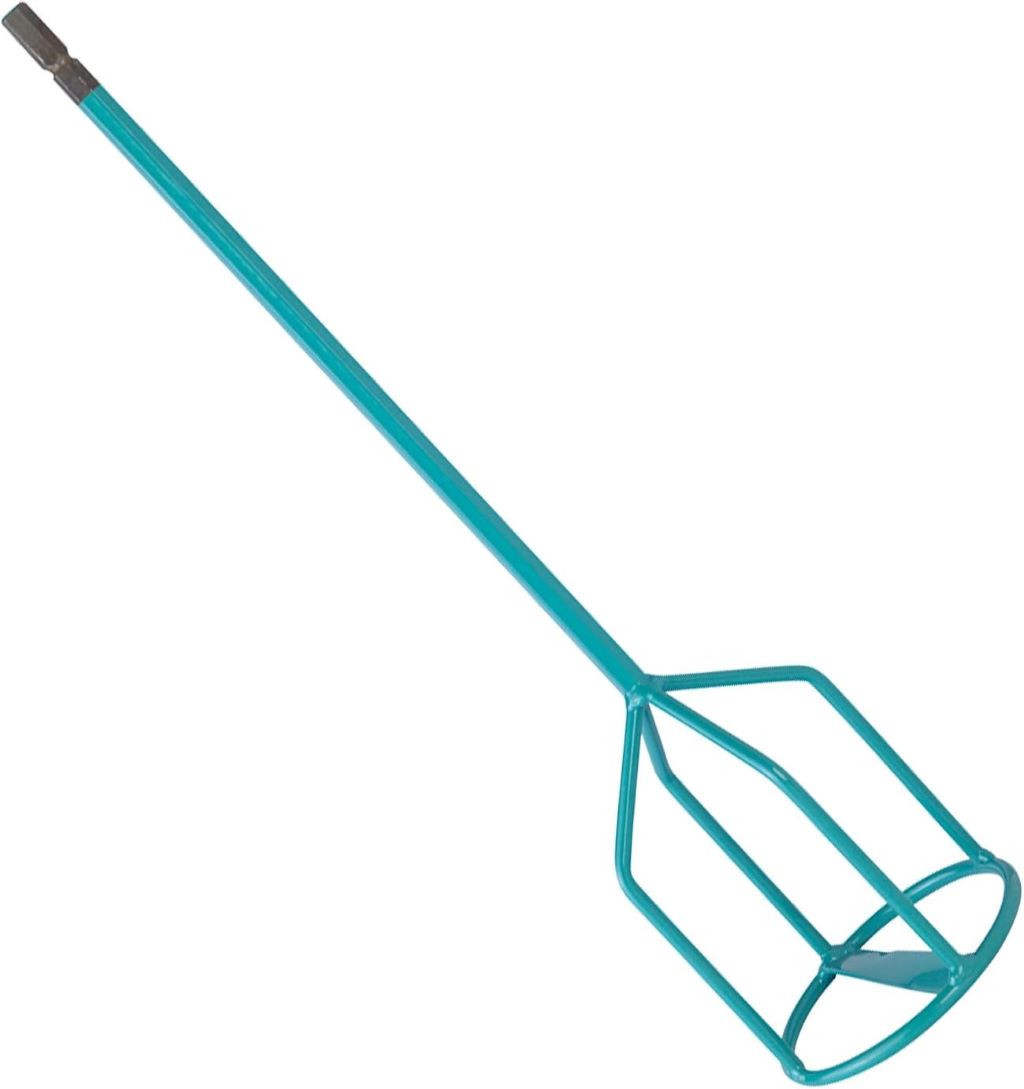

German engineering sets the Collomix KR120HF apart from generic mixing tools. The paddle’s bird cage design creates optimal material flow patterns that eliminate common mixing problems. The KR mixing paddle generates high shear forces which prevent the formation of lumps and ensure that the material is homogenized quickly.

The crossbar feature addresses a critical mixing challenge. The crossbar helps scrape material cleanly off the bottom of the tub. This design element prevents material waste and ensures complete mixing throughout the entire batch. Additionally, the paddle maintains excellent corner smoothness in mixing containers, reaching areas that conventional paddles miss.

Professional contractors appreciate the 23-inch shaft length, which accommodates standard mixing buckets while maintaining proper leverage. The 4.75-inch diameter provides sufficient mixing coverage without creating excessive turbulence that introduces air bubbles into sensitive materials.

Versatile Material Compatibility

The Collomix KR120HF excels across diverse construction applications. For self-levelling materials, adhesives, sealants, fillers, epoxy mixes, etc. This versatility eliminates the need for multiple specialized paddles, streamlining tool inventory and reducing equipment costs.

Flooring professionals particularly value its performance with tile adhesives and thin-set mortars. The paddle’s horizontal swirling action creates optimal mixing patterns for these sticky materials. Material is swirled horizontally, with the components flowing up and down in accordance with the movement of the mixing tool.

The tool handles cement-based products with equal efficiency. Pointing mortars, cement plasters, and joint compounds achieve consistent texture without the clumping issues common with inferior paddles. This consistent performance translates to predictable application characteristics and superior finished results.

Performance Advantages That Matter

Professional results depend on mixing quality, and the KR120HF delivers measurable performance improvements. Fewer air inclusions in the material and generally higher shear forces prevent the formation of lumps. These technical advantages translate directly to job site benefits that contractors notice immediately.

The parallel mixing action creates superior material homogenization compared to conventional paddle designs. This action produces smoother textures while requiring less mixing time, which improves productivity on demanding schedules. The reduced air incorporation is particularly valuable for adhesives and sealants where air bubbles compromise bond strength.

Material waste drops significantly when using the KR120HF. The efficient scraping action and thorough mixing reduce material left behind in containers. Over the course of multiple projects, these material savings often justify the paddle’s investment cost.

Real-World Performance and User Experience

Construction professionals report consistently positive experiences with the Collomix KR120HF across various job conditions. Tile contractors appreciate how it handles thick adhesives that challenge conventional paddles. The paddle maintains consistent mixing quality even with viscous materials that bog down inferior tools.

Flooring installers note significant time savings during material preparation. The efficient mixing action reduces preparation time per batch, allowing faster project completion without compromising quality. This time efficiency becomes particularly valuable on large installations where multiple batches are required.

The paddle’s durability impresses users who subject it to demanding job site conditions. The powder-coated finish resists corrosion and material buildup, maintaining performance characteristics throughout extended use. Strong welded joints withstand the stress of mixing heavy materials without developing weak points that plague cheaper alternatives.

Technical Specifications and Compatibility

The KR120HF features Hexafix connection compatibility, ensuring secure attachment to Collomix mixing machines. The inclusion of a 3/4″ Hexafix chuck size means paddle changes are quick and hassle-free, further enhancing your productivity. This quick-change capability minimizes downtime between different material types.

Mixing capacity ranges from 4.0 to 6.6 gallons, making it ideal for standard construction batch sizes. This capacity matches typical 50-pound material bags, reducing waste and simplifying batch calculations. The paddle works effectively with both bucket and container mixing setups commonly used on construction sites.

The continuous guard ring design protects both the paddle and mixing container from damage during operation. This protective feature extends equipment life while preventing costly container replacements. The smoothly rotating guard ring also contributes to the paddle’s efficient mixing action.

Pros and Cons Analysis

Advantages:

- Superior lump prevention through high shear forces

- Excellent material compatibility across construction applications

- Durable German construction with welded joints

- Quick Hexafix connection system for efficient paddle changes

- Effective corner cleaning and bottom scraping action

- Reduced air incorporation compared to conventional paddles

Limitations:

- Higher initial cost compared to basic mixing paddles

- Requires compatible Hexafix mixing machines

- May be oversized for very small batch applications

- Professional-grade tool complexity exceeds basic DIY needs

Featured Snippet: Why Choose the Collomix KR120HF?

What makes the Collomix KR120HF mixing paddle superior for professional construction work?

The Collomix KR120HF stands out through its German-engineered bird cage design that generates high shear forces, preventing lump formation while ensuring rapid material homogenization. Its horizontal swirling action reduces air inclusions, making it ideal for tile adhesives, self-leveling compounds, and cement-based materials. The paddle features a crossbar for complete bottom scraping, 23-inch shaft length for standard bucket compatibility, and Hexafix quick-change connection. Professional contractors value its consistent performance across viscous materials, time-saving efficiency, and durable construction that withstands demanding job site conditions. The tool handles 4.0-6.6 gallon batches effectively, matching typical 50-pound material bags while reducing waste and preparation time.

Frequently Asked Questions

Q: Can the KR120HF handle thick epoxy resins?

A: Yes, the paddle’s high shear forces and horizontal mixing action make it excellent for epoxy resins and other viscous materials. The design prevents air bubble incorporation that can weaken epoxy bonds.

Q: What mixing machines are compatible with this paddle?

A: The KR120HF features Hexafix connection, making it compatible with Collomix Xo series mixers and other machines with 3/4-inch Hexafix chucks.

Q: How does cleaning compare to standard paddles?

A: The powder-coated finish and smooth design make cleaning significantly easier. Material doesn’t stick as readily, and the paddle rinses clean more quickly than conventional designs.

Q: Is this paddle suitable for small DIY projects?

A: While it will work for smaller projects, the KR120HF is designed for professional applications with 4.0-6.6 gallon mixing capacity. Smaller projects might not utilize its full capabilities efficiently.

Final Thoughts

The Collomix KR120HF Mixing Paddle represents a significant upgrade for construction professionals serious about mixing quality and efficiency. Its German engineering delivers consistent, professional results that justify the investment through improved productivity and reduced material waste.

However, this paddle’s professional-grade features may exceed requirements for occasional users or small-scale projects. The investment makes most sense for contractors regularly mixing adhesives, sealants, and cement-based materials where consistent quality directly impacts project success. Read More: Powerful And Portable: SILVEL 2300W Cement Mixer Review

For professionals seeking reliable mixing performance that eliminates common problems like lumping and incomplete homogenization, the KR120HF provides a proven solution backed by German engineering excellence.

Ready to upgrade your mixing capabilities? Consider the Collomix KR120HF for your next project and experience the difference professional-grade tools make in achieving consistent, high-quality results. Visit your local construction supply dealer or authorized Collomix distributor to see this paddle in action.