Imagine this: you’re in your woodworking shop, setting up a miter saw for a precise cut, but your tape measure keeps slipping, throwing off your measurements by a frustrating 1/32 of an inch. Sound familiar? For woodworkers, precision is everything, and a sticky measuring tape can be a game-changer. These adhesive-backed tools are designed to stay put, ensuring accurate measurements for jigs, fences, and other setups. In this guide, we’ll dive deep into the world of sticky measuring tapes, exploring their benefits, how to choose the best one, and tips for using them effectively in your woodworking projects. Whether you’re a seasoned craftsman or a DIY enthusiast, this article will help you elevate your precision and efficiency.

What Is a Sticky Measuring Tape?

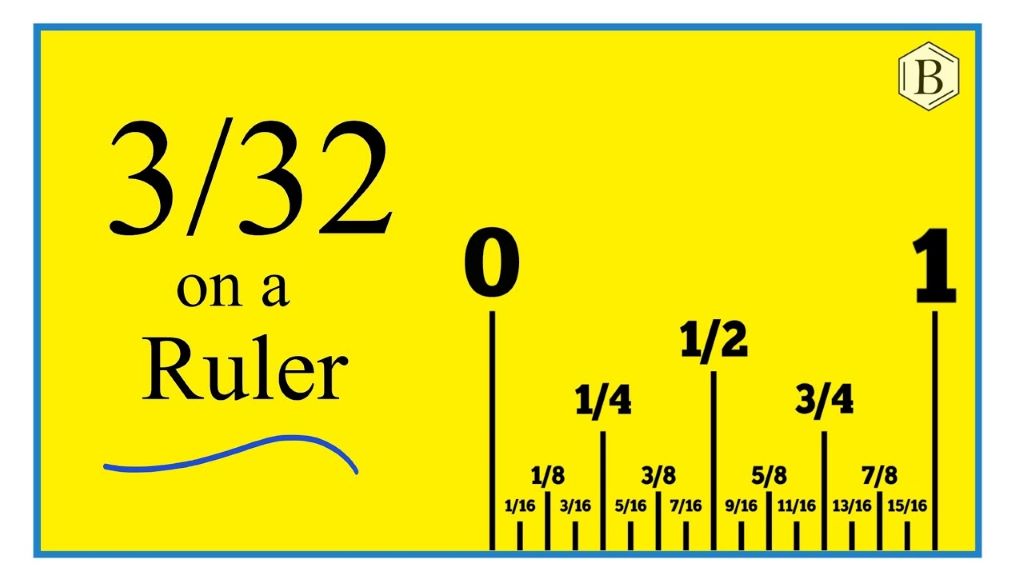

A sticky measuring tape, also known as an adhesive-backed measuring tape or self-adhesive ruler, is a specialized tool designed for woodworking and other precision tasks. Unlike traditional tape measures, these tapes feature a strong adhesive backing that allows them to be affixed to surfaces like table saws, miter saw fences, or router tables. Typically made from durable materials like steel or vinyl, they provide clear, easy-to-read measurements in imperial or metric units, often with increments as fine as 1/32 inch or 1 millimeter.

Sticky measuring tapes are ideal for repetitive tasks where consistent measurements are critical, such as setting stop blocks or aligning cuts. They come in various lengths (commonly 6 to 12 feet) and orientations (left-to-right or right-to-left), making them versatile for different tools and setups. Their ability to stay fixed eliminates the hassle of holding a tape measure in place, freeing up your hands for more important tasks.

Why Use Sticky Measuring Tapes in Woodworking?

Woodworking demands accuracy, and even a slight measurement error can ruin a project. Sticky measuring tapes offer several advantages that make them indispensable in the shop:

-

Enhanced Precision

Sticky tapes stay securely in place, reducing the risk of slippage that can occur with handheld tape measures. This ensures consistent measurements, especially when setting up jigs or fences. For example, when cutting multiple pieces to the same length, a sticky tape on your miter saw fence allows you to set a stop block with confidence, knowing each cut will be identical.

-

Time-Saving Efficiency

By eliminating the need to repeatedly measure and mark, sticky tapes streamline your workflow. You can quickly reference measurements directly on your tool, saving time on projects like cabinetry or furniture making. This is particularly useful for batch production, where speed and consistency are key.

-

Versatility Across Tools

Sticky measuring tapes can be applied to a variety of woodworking tools, including table saws, radial arm saws, drill presses, and router tables. Their flexibility makes them a must-have for any shop, whether you’re a hobbyist or a professional.

-

Durability

High-quality sticky tapes are designed to withstand the rigors of a woodworking environment. Many are made from materials like stainless steel or coated vinyl, resisting wear, tear, and exposure to dust or moisture. Some brands, like FastCap, offer tapes with protective coatings for added longevity.

-

Ease of Use

With clear, high-contrast markings, sticky tapes are easy to read, even in low-light conditions. Many also feature repositionable adhesives, allowing you to adjust their placement without damaging surfaces.

Choosing the Right Sticky Measuring Tape

Not all sticky measuring tapes are created equal. To ensure you’re getting a reliable product, consider the following factors when making your selection:

-

Accuracy

Accuracy is paramount in woodworking. Look for tapes with precise, laser-etched markings. Some brands, like Starrett, are known for their high-quality standards, but user reviews suggest even premium tapes can vary by up to 1/32 inch. Always verify accuracy against a trusted ruler, such as a Woodpecker or Starrett rule, before committing to a project.

-

Material and Durability

Choose a tape made from durable materials like stainless steel or reinforced vinyl. Metal-backed tapes, like those from Kreg, are less likely to stretch or deform over time. Avoid plastic-based tapes, as they may stretch slightly during application, leading to inaccuracies.

-

Orientation

Sticky tapes come in left-to-right and right-to-left orientations to suit different tools and user preferences. For example, a right-to-left tape is ideal for the right side of a table saw blade, while a left-to-right tape works better on the left. Some brands, like Rockler, offer both options to accommodate various setups.

-

Adhesive Strength

The adhesive should be strong enough to stay in place but not so aggressive that it damages your equipment when removed. Look for repositionable adhesives, like those found on FastCap’s Peel & Stick Tape, which allow for easy adjustments without leaving residue.

-

Measurement System

Decide whether you need imperial, metric, or dual-scale markings based on your projects. In the U.S., imperial measurements (inches and fractions) are standard, but metric tapes are useful for international plans or precision work. Dual-scale tapes offer flexibility for diverse projects.

-

Length and Width

Choose a tape length that suits your tools. A 6-foot tape is sufficient for most miter saws, while longer tapes (10-12 feet) are better for table saws or large jigs. Wider tapes (around 3/4 inch) are easier to read but may not fit in tight spaces, so balance visibility with practicality.

-

Brand Reputation

Trusted brands like FastCap, Kreg, Rockler, and Starrett are popular among woodworkers for their reliability. However, user feedback on platforms like Sawmill Creek suggests that even well-known brands can have inconsistencies, so read reviews and test your tape before use.

Top Sticky Measuring Tapes for Woodworking

Here are some highly recommended sticky measuring tapes based on quality, user feedback, and performance:

- FastCap Peel & Stick Tape: Known for its durable vinyl construction and clear markings, this tape is a favorite for table saws and miter stations. It’s available in multiple orientations and lengths, with a repositionable adhesive for easy adjustments.

- Rockler Adhesive-Backed Measuring Tape: This 6-foot tape is ideal for miter saws and radial arm saws, offering both left-to-right and right-to-left options. Its steel construction ensures durability, though some users report minor inaccuracies.

- Kreg Self-Adhesive Measuring Tape: With a metal backing and precise markings, Kreg’s tape is a reliable choice for table saws and router tables. It’s designed to resist stretching and wear, making it a long-lasting option.

- Starrett Adhesive Tape: While Starrett is synonymous with precision, some users have reported inconsistencies in their sticky tapes. If choosing Starrett, verify accuracy before use.

Tips for Using Sticky Measuring Tapes Effectively

To maximize the benefits of your sticky measuring tape, follow these best practices:

-

Surface Preparation

Before applying the tape, clean the surface thoroughly to remove dust, oil, or debris. A clean, dry surface ensures strong adhesion and prevents peeling. Use isopropyl alcohol for a residue-free clean.

-

Test for Accuracy

Always compare your sticky tape’s measurements against a high-quality ruler or caliper before starting a project. Even a 1/32-inch error can compound over multiple cuts, leading to gaps in joinery or misaligned parts.

-

Apply Without Stretching

When applying the tape, avoid pulling it taut, as this can stretch the material and skew measurements. Lay it down gently, smoothing it out to ensure it adheres evenly.

-

Use with Stop Blocks

Sticky tapes shine when paired with stop blocks for repetitive cuts. Set your stop block to the desired measurement on the tape, and you’ll get consistent results every time. This is especially useful for cutting multiple pieces to the same length, such as drawer fronts or shelf supports.

-

Protect the Tape

To extend the life of your tape, avoid exposing it to excessive moisture or abrasive materials. Consider applying a clear protective film over the tape for added durability, especially in high-traffic areas of your shop.

-

Combine with Other Tools

For ultra-precise work, use your sticky tape in conjunction with a hook rule or digital caliper. Sticky tapes are great for quick references, but for joinery or fine measurements, a secondary tool can confirm accuracy.

Common Challenges and Solutions

While sticky measuring tapes are incredibly useful, they’re not without challenges. Here are some common issues and how to address them:

- Inaccuracy

Some tapes, even from reputable brands, may have inconsistent markings. To avoid this, test the tape against a known standard before use. If inaccuracies persist, consider a metal ruler or a different brand.

- Adhesive Failure

If the tape starts peeling, it may be due to a dirty surface or low-quality adhesive. Reapply the tape after cleaning the surface, or opt for a tape with a stronger adhesive, like FastCap’s SpeedTape.

- Wear and Tear

Heavy use can wear down markings over time. Choose a tape with a protective coating or replace it periodically to maintain readability. Some woodworkers apply a clear sealant to preserve the tape’s markings.

SEO Tips for Woodworking Blogs Featuring Sticky Measuring Tapes

If you’re writing about sticky measuring tapes for your woodworking blog, here are some SEO strategies to boost visibility while adhering to Google’s helpful content guidelines:

- Target Long-Tail Keywords: Use phrases like “best adhesive measuring tape for woodworking” or “how to use sticky tape for miter saw” to capture specific user intent.

- Incorporate LSI Keywords: Include terms like “precision woodworking tools,” “self-adhesive ruler,” and “measuring tape for table saw” naturally throughout the content.

- Answer User Questions: Address common queries, such as “Are sticky measuring tapes accurate?” or “How do I apply a sticky tape to my table saw?”

- Use Engaging Headings: Break up the content with descriptive H2 and H3 headings to improve readability and scannability.

- Add Visuals: Include images or videos showing how to apply and use sticky tapes to enhance user engagement and dwell time.

- Link to Authoritative Sources: Reference trusted woodworking sites or product pages (e.g., Rockler, FastCap) to build credibility.

Conclusion: Elevate Your Woodworking with Sticky Measuring Tapes

Sticky measuring tapes are a small but powerful addition to any woodworking shop. By providing reliable, hands-free measurements, they save time, improve accuracy, and streamline your workflow. Whether you’re setting up a table saw, aligning a miter saw fence, or building a custom jig, these tapes can make a significant difference in your projects’ quality. By choosing a high-quality tape, applying it correctly, and pairing it with other precision tools, you’ll achieve professional results with ease.

Ready to upgrade your woodworking precision? Explore top-rated sticky measuring tapes from brands like FastCap, Kreg, or Rockler, and start measuring with confidence. Have a favorite sticky tape or a tip for using it? Share your thoughts in the comments below, or join the conversation on social media to connect with other woodworkers!

Read More:

Mastering the Circuit Tester Guide for DIY Enthusiasts and Professionals